QR Series Linear Guideway

QR Series Linear Guideway

QR Series Linear Guideway also called Quiet Roller Type Linear Guideway

QR series offer super high rigidity and high load capacities. The SynchMotionTM Technology offers quiet operation.

Low noise design less than 3 dB

Radial rigidity up to 5,412 N/µm

Static load rating up to 572 KN

Quiet Roller Type Linear Guideway Application

CNC machining centers

Heavy duty cutting machines

Grinding machines

Injection molding machines

Electric discharge machines

Wire cutting machines

Gantry machine

Product Details

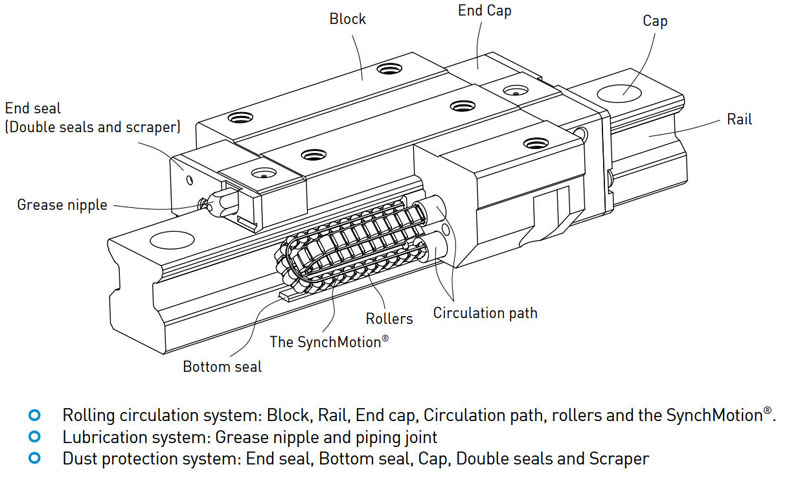

Quiet roller linear guideway are industrial components designed for low-noise, high-precision motion requirements. Their core feature lies in using rollers as the rolling elements and employing synchronous coupling technology to achieve quiet and smooth movement.

QR Series Linear Guideway Main Features

1. Low-Noise Design: The rollers are evenly arranged using a synchronous coupling, eliminating collision noise between adjacent rollers. Noise levels are reduced by approximately 3 decibels compared to traditional guides, making them suitable for noise-sensitive environments (such as electronics manufacturing and medical equipment).

2. High Load Capacity: Utilizing a DB (45°-45°) contact system, it can withstand high loads in four directions (vertical, horizontal, and vertical), making it suitable for heavy-duty applications (such as logistics conveying systems and large robots).

3. Smooth Motion: The synchronous coupling ensures simultaneous roller movement, reducing frictional resistance fluctuations and improving motion stability.

QR Series Linear Guideway Applications

1. Electronics Industry: Precision equipment requiring high speed, quiet operation, and low dust generation (such as semiconductor manufacturing equipment).

2. Heavy Industrial Equipment: Such as large robots and logistics conveying systems, relying on high load-bearing capacity and resistance to lateral forces.

3.Medical and laboratory equipment: Scenarios with stringent requirements for noise and precision.

Selection Recommendations

Compared to ball bearing guides: Roller guides offer higher load capacity but are more expensive. Selection should be based on a comprehensive consideration of load, precision, and budget.

QR series offers super high rigidity and very high load capacities. The QR series with SynchMotion Technology offerslow friction, smooth movement, guieter operation and longer running life. in the industry where high accuracy, lownoise and high rigidity is required, the QR series is interchangeable with the RG series.

Advantages Quiet Roller Type Linear Guideway Feature

1. Super high load capacity in linear guideway, with the four rows of rollersarranged at a contact angle of 45-degrees, the QR series linear guideway hasequal load ratings in the radial, reverse radial and lateral directions, The QRseries has a higher load capacity in a smaller size than conventional, ball-typelinear guideways.

2. Low Noise Design With SynchMotion technology, rolling elements are interposed between the partitions of SynchMotion to provide improved circulation. Due to the elimination of contact between the rolling elementscollision noise and sound levels are drastically reduced.

3. Smooth Movement in standard linear guideways, rolling elements on the load side of the quide block begin rollincand push their way through the raceway. When they contact other rolling elements they create counter-rotationafriction, This results in a great variation of rolling resistance, The QR linear quideway, with SvnchMotion’technology prevents this condition.

4. The QR series is a type of linear guideway that uses rollersas the rolling elements. Elastic deformation of the linearcontact surface, during load, is greatly reduced therebyoffering greater rigidity and higher load capacities in all 4 load directions.

Relatd Products

What Our Customers Said?

FAQ

Yeah, we have some standard in stock. Including Ball screw with nut, linear guide rail and block, linear module, linear motor and servo motor.

Yes, we can manfacture ballscrew according to customers’ size details drawing or specification, and please offer us below details

1, Ballscrew diameter

2, Thread lead

3, Thread lenght and total ballscrew length

4, End journal configuration

5, Nut configuration

6, Accuracy(lead deviation, geometrical tolerance)

7, Working speed

8, Maximum static load, working load, preload drag torque)

9, Nut safety requirement

10, Lubrication

Usually 45 working delivery days for C5 and P5 accuracy ball screw, but for C7-C10 ballscrew just need 15 working days.

From 50W to 1500W.

We have our own brand, but also we offer HIWIN, Delta, Leadshine, Mitsubishi and others famous brand motor.

Yes, but you need inform us details requirement we need, then our engineer can help you design.

Standard parts: 7-15days.

Non-standard parts: 15-25days.

We will make the delivery as soon as possible with the guarantee quality.

By T/T, for samples 100% with the order; over US $10000, 30% paid for deposit by T/T before production arrangement, the balance to be paid before shipment.

Yes, we can receive.