PG series linear guideway

PG series linear guideway

PG series linear guideway is positioning linear guideway

Precision positioning linear guideway are the core components for achieving high-precision linear motion, and their performance directly affects the positioning accuracy, operational stability, and service life of the equipment.

Positioning Linear Guideway Feature

The magnetic encoder is built into the rail,which maintains high rigidity, accuracy and resolution. It can also withstand humidity, high-temperature environments, and vibration applications.

Resolution 1 µm

Repeatabilty ±2 µm

Ingress protection (IP) rating IP67

Positioning Linear Guideway Application

Utomation machinery

Manufacturing machinery

Cutting/Finishing Electronic machinery

Medical X-ray/MRI/CAT- scan

Transportation

Construction

Product Details

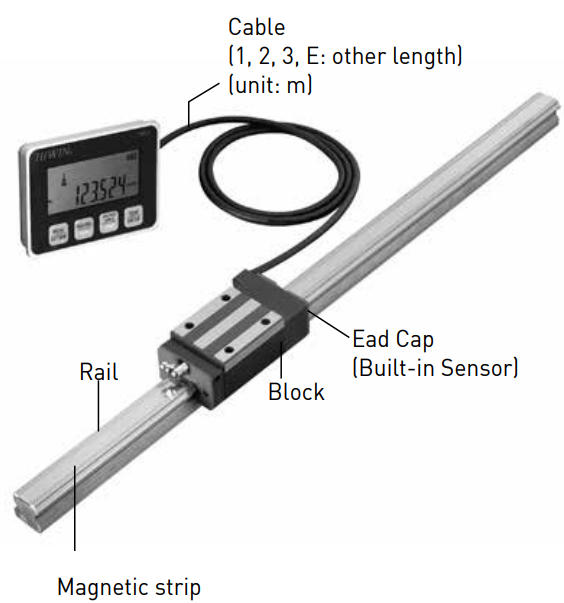

PG Series Positioning Linear Guideway Construction

The PG is a linear guideway assembly integrated with a magneticencoder for position measurement.

Positioning Linear Guideway Features

1. Magnetic encoder is built into the rail, saving installation space.

2. Maintains high rigidity as well as high accuracy.

3. Both the sensor and the magnetic strip are protected fromharmful external contaminants such as dust, iron chips, etc.

4.Non-contact measuring sensor for longer life.

5. Can measure distances up to 25 m.

6.Can withstand humidity and high-temperature environmentsalong with oily, dusty and high vibration applications.

7. High resolution

8. Easy installation

Proper installation is crucial for ensuring guide rail accuracy.

The main principles include:

1. Reference Side Positioning: Typically, only the reference side guide rail needs positioning (e.g., using locating pins or milling grooves). Non-reference side guide rails are adjusted using the reference side as the reference.

2. High-Precision Scenarios: For applications requiring extremely high precision and rigidity, both guide rail sides should be positioned and equipped with lateral clamping devices.

3. Anti-Overflow Design: Locating pin holes are designed on the base plate for precise positioning, and slider limits are added to prevent accidental slider slippage.

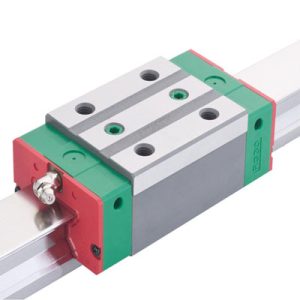

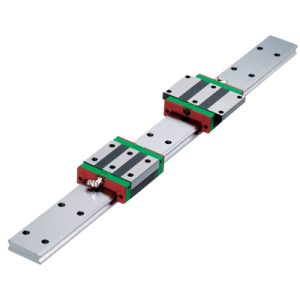

Relatd Products

What Our Customers Said?

FAQ

Yeah, we have some standard in stock. Including Ball screw with nut, linear guide rail and block, linear module, linear motor and servo motor.

Yes, we can manfacture ballscrew according to customers’ size details drawing or specification, and please offer us below details

1, Ballscrew diameter

2, Thread lead

3, Thread lenght and total ballscrew length

4, End journal configuration

5, Nut configuration

6, Accuracy(lead deviation, geometrical tolerance)

7, Working speed

8, Maximum static load, working load, preload drag torque)

9, Nut safety requirement

10, Lubrication

Usually 45 working delivery days for C5 and P5 accuracy ball screw, but for C7-C10 ballscrew just need 15 working days.

From 50W to 1500W.

We have our own brand, but also we offer HIWIN, Delta, Leadshine, Mitsubishi and others famous brand motor.

Yes, but you need inform us details requirement we need, then our engineer can help you design.

Standard parts: 7-15days.

Non-standard parts: 15-25days.

We will make the delivery as soon as possible with the guarantee quality.

By T/T, for samples 100% with the order; over US $10000, 30% paid for deposit by T/T before production arrangement, the balance to be paid before shipment.

Yes, we can receive.