High Lead Ball Screw

High Lead Ball Screw

High lead ball screws are high-precision transmission components that convert rotary motion into linear motion. They have a large lead (the linear distance the nut travels in one revolution of the screw), making them suitable for applications requiring rapid movement or large stroke transmission.

High Lead Ball Screw Key Selection Parameters:

Lead (L): Determines the travel speed and must be matched with the motor speed.

Nominal diameter (d): Affects load-bearing capacity and rigidity; a larger diameter results in a stronger load.

Precision grade: such as C7, C10, selected according to equipment requirements.

Product Details

High Lead Ball Screw Features

It is important for a High-lead Ballscrew to be with characteristics of high rigidity, low noise and thermal control. PMI ‘s designs and treatments are taken for following:

1. High DN Value

The DN value can be 130,000 in normal case. For some special cases, for example in a fixed ends case, the DN value can be as high as 140,000. Please contact our engineers for this special application.

2. High Speed

PMI ‘s High-speed Ballscrews provide 100 m/min and even higher traverse speed for machine tools for high performance cutting.

3. High Rigidity

Both the screw and ballnut are surface hardened to a specific hardness and case depth to maintain high rigidity and durability.

Multiple thread starts are available to make more steel balls loaded in the ballnut for higher rigidity and durability.

4. Low Noise

Special design of ball circulation tubes offer smooth ball circulation inside the ballnut. It also makes safe ball fast running into the tubes without damaging the tubes.Accurate ball circle diameter (BCD) through whole threads for consistent drag torque and low noise.

High Lead Ball Screw Application:

1. High-speed equipment: such as automated production lines and laser cutting machines, where rapid positioning is required.

2. Heavy-duty machinery: such as gantry machining centers and presses, requiring high rigidity designs.

3. Precision instruments: medical equipment and semiconductor manufacturing, relying on high precision and stability.

Relatd Products

What Our Customers Said?

FAQ

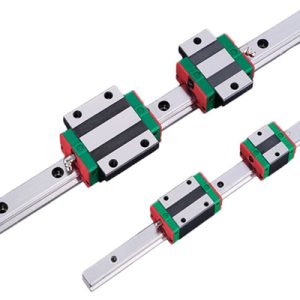

Yeah, we have some standard in stock. Including Ball screw with nut, linear guide rail and block, linear module, linear motor and servo motor.

Yes, we can manfacture ballscrew according to customers’ size details drawing or specification, and please offer us below details

1, Ballscrew diameter

2, Thread lead

3, Thread lenght and total ballscrew length

4, End journal configuration

5, Nut configuration

6, Accuracy(lead deviation, geometrical tolerance)

7, Working speed

8, Maximum static load, working load, preload drag torque)

9, Nut safety requirement

10, Lubrication

Usually 45 working delivery days for C5 and P5 accuracy ball screw, but for C7-C10 ballscrew just need 15 working days.

From 50W to 1500W.

We have our own brand, but also we offer HIWIN, Delta, Leadshine, Mitsubishi and others famous brand motor.

Yes, but you need inform us details requirement we need, then our engineer can help you design.

Standard parts: 7-15days.

Non-standard parts: 15-25days.

We will make the delivery as soon as possible with the guarantee quality.

By T/T, for samples 100% with the order; over US $10000, 30% paid for deposit by T/T before production arrangement, the balance to be paid before shipment.

Yes, we can receive.