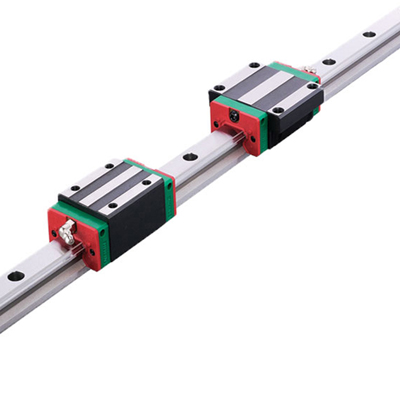

Heavy Load Ball Linear Guideway

Heavy Load Ball Linear Guideway

Heavy Load Ball Linear Guideway is HG series linear quideways

Heavy Load Ball Type Linear Guideway Feature

Features equal load ratings from all directions and with self-aligning capability to absorb installation errors, thus achieving high accuracy.

Steel balls contact angle: 45°

Radial rigidity up to: 1,599 N/µm

Maximum static load: 420 KN

Heavy Load Ball Linear Guideway APPLICATION

Grinding machine; Milling machine

Drilling machine; Lathe; Machining center;

EDM;

Boring Machine; Wire cut;

Precision testing machine; Wood working;

Transportation equipment

Product Details

Heavy Load Ball Linear Guideway (HG series linear guideway) are designed with load capacity and rigidity higher than other similar products withcircular-arc aroove and structure optimization, it features eaual load ratinas in the radial reverse radial and lateradirections, and self-aligning to absorb installation-error. Thus, HG series linear guideways can achieve a longlife with high speed, high accuracy and smooth linear motion.

Features of Heavy Load Ball Linear Guideway

1. Self-aligning capability

By design, the circular-arc aroove has contact points at 45 deqrees. HG series can absorb most installation errors dueto surtace irregularities and provide smooth linear motion through the elastic deformation of rollina elements ancthe shift of contact points. Self-aligning capability, high accuracy and smooth operation can be obtained with an easlinstallation.

2. Interchangeability

Because of precision dimensional control, the dimensional tolerance of HG series can be kept in a reasonable rangewhich means that any blocks and any rails in a specific series can be used together while maintaining dimensionaltolerance. And a retainer is added to prevent the balls from faling out when the blocks are removed from the rail.

3. Hiah rigidity in all four directions

Because of the four-row design, the HG series linear guideway has equal load ratings in the radial, reverse radialand lateral directions. Furthermore, the circular-arc groove provides a wide-contact width between the balls and thegroove raceway allowing large permissible loads and high rigidity.

Heavy Load Ball Linear Guideway Structural

Relatd Products

What Our Customers Said?

FAQ

Yeah, we have some standard in stock. Including Ball screw with nut, linear guide rail and block, linear module, linear motor and servo motor.

Yes, we can manfacture ballscrew according to customers’ size details drawing or specification, and please offer us below details

1, Ballscrew diameter

2, Thread lead

3, Thread lenght and total ballscrew length

4, End journal configuration

5, Nut configuration

6, Accuracy(lead deviation, geometrical tolerance)

7, Working speed

8, Maximum static load, working load, preload drag torque)

9, Nut safety requirement

10, Lubrication

Usually 45 working delivery days for C5 and P5 accuracy ball screw, but for C7-C10 ballscrew just need 15 working days.

From 50W to 1500W.

We have our own brand, but also we offer HIWIN, Delta, Leadshine, Mitsubishi and others famous brand motor.

Yes, but you need inform us details requirement we need, then our engineer can help you design.

Standard parts: 7-15days.

Non-standard parts: 15-25days.

We will make the delivery as soon as possible with the guarantee quality.

By T/T, for samples 100% with the order; over US $10000, 30% paid for deposit by T/T before production arrangement, the balance to be paid before shipment.

Yes, we can receive.