End Deflector Ball Screw

End Deflector Ball Screw

End Deflector Ballscrew Features

It is important for a high-lead ballscrew to be with characteristics of high rigidity, low noise and thermal control. PMI takes its patented design and treatments to achieve the following

End Deflector Ball Screw Applications

1. CNC Machinery

2. Precision Machinery

3. High Speed Machinery

4. Semi-Conductor Equipment

5. Medical equipment

Product Details

End Deflector Ball Screw Characteristics:

1. High DN Value

Max. DN Value: 220,000

2. Low Noise

The average and accurate ball circle diameter (BCD) through whole threads make the ballscrews to obtain the stable and consistent drag torque as well as to reduce the noise. The audio frequency is low and deep due to the designed of plastic circulation system.

Space Saving

The ballnut diameter reduces 20%~25% substantially and the length of nut is shorter. The total space shall be reduced to approximately 50% consequently.

3. Circulation

The specially designed pathway of the Recirculation System makes a contact with lead angle and also with BCD in the same tangency, improving its smoothness eff ectively.

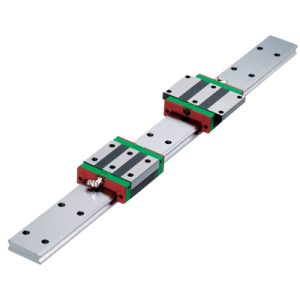

Relatd Products

What Our Customers Said?

FAQ

Yeah, we have some standard in stock. Including Ball screw with nut, linear guide rail and block, linear module, linear motor and servo motor.

Yes, we can manfacture ballscrew according to customers’ size details drawing or specification, and please offer us below details

1, Ballscrew diameter

2, Thread lead

3, Thread lenght and total ballscrew length

4, End journal configuration

5, Nut configuration

6, Accuracy(lead deviation, geometrical tolerance)

7, Working speed

8, Maximum static load, working load, preload drag torque)

9, Nut safety requirement

10, Lubrication

Usually 45 working delivery days for C5 and P5 accuracy ball screw, but for C7-C10 ballscrew just need 15 working days.

From 50W to 1500W.

We have our own brand, but also we offer HIWIN, Delta, Leadshine, Mitsubishi and others famous brand motor.

Yes, but you need inform us details requirement we need, then our engineer can help you design.

Standard parts: 7-15days.

Non-standard parts: 15-25days.

We will make the delivery as soon as possible with the guarantee quality.

By T/T, for samples 100% with the order; over US $10000, 30% paid for deposit by T/T before production arrangement, the balance to be paid before shipment.

Yes, we can receive.