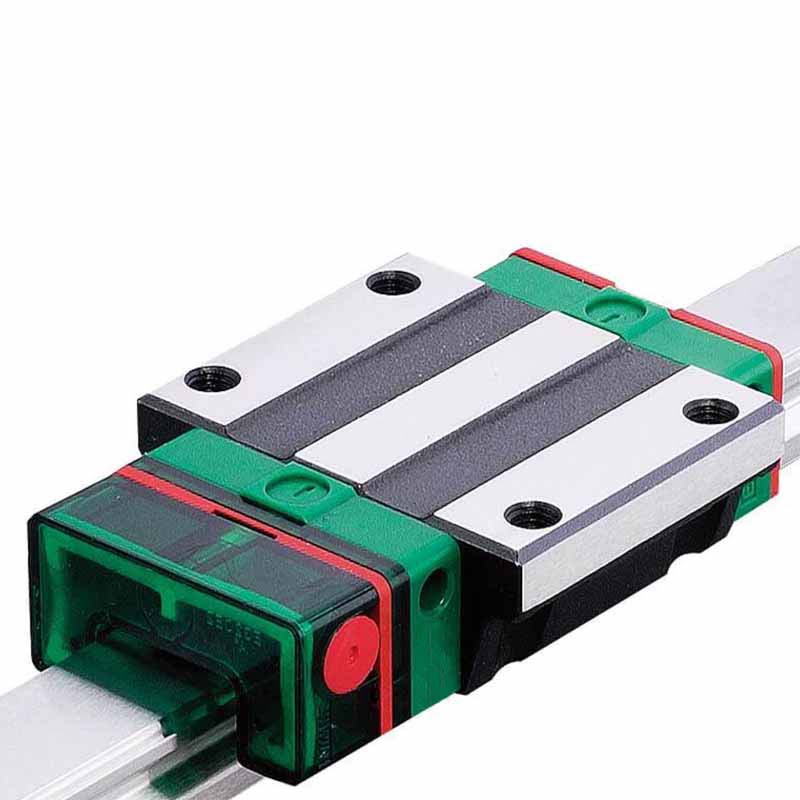

E2 Series Linear Guideway

E2 Series Linear Guideway

E2 Series Linear Guideway is Self lubrication Kit for Linear Guideway

E2 Series Linear Guideway Feature is reducing oil usage and easy to maintain. The oil tank can be added or removed easily.

Cost saving lubrication free

Easy installation Replaceable

Extend maintenance period up to 10000 KM

E2 Series Linear Guideway Application

Automation equipment

Industrial machine

Electronic machine

Medical equipment

Transportation

Construction

Product Details

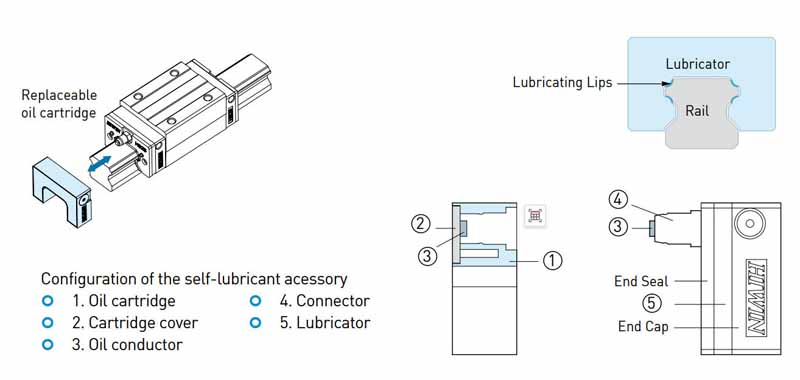

Construction of E2 Series Linear Guideway

E2 self-lubricating linear guideway contains a lubricator between the end cap and end seal. Outside of the block isequipped with a replaceable oil cartridge, the confiquration of which is listed below.

Lubrication oil flows from the replaceable oil cartridge to the lubricator and then lubricates arooves of rails.

The Oilcartridge comprises a oil conductor with 3D structure that enables the lubricator to contact oil despite that blocks areplaced at a random position , and thus the lubrication oil inside the oil cartridge can be used up via capillary action.

Feature of E2 Series Self lubrication Kit for Linear Guideway

1. Cost reduction: Save costs by reducing oil usage and maintenance.

2. Clean and environmentally friendly: Optimized oil usage prevents leaking, making it the ideal solution for cleanworking environments.

3. Long lasting and low maintenance: Self-lubricating block is maintenance free in most applications

4. No installation limitations: The linear guideway can be lubricated by E2 self-lubricating module irrespective ofmounting directions.

5. Easy to be assembled and disassembled: The cartridge can be added or removed from the block even when thequideway is installed on a machine.

6. Diferent oils can be selected: The replaceable oil cartridge can be refilled with any approved lubrication oildepending on different requirements.

7. Applications for special environments: Sealing grease into the block leads to better lubrication effects, especially in dusty, dirty,or wet environments.

E2 Series Self lubrication Kit for Linear Guideway Main Advantages

1. Maintenance-free design: Built-in automatic grease circulation reduces the frequency of manual lubrication, with a maintenance interval of up to 10,000 kilometers;

2. High environmental adaptability: Dustproof structure effectively blocks dust and debris, suitable for harsh environments such as dust and moisture;

3. Economical: Saves on lubrication equipment investment and oil consumption, resulting in lower long-term operating costs.

E2 Series Self lubrication Kit for Linear Guideway Lubrication Capability

1. Life testing with light load

2. Characteristic of lubricating oil

The standard oil is a fully synthetic lubricant with a main constituent, synthetic hydrocarbons lPA0). The viscosity classof the oil is 680 (lS0 VG680).lts characteristics are as follows.

(1) Compatible with lubrication grease of which the base oil is synthetic hydrocarbon oil, mineral oil or ester oil

(2) Synthetic oil with superb high temperature thermaloxidation resistance.

(3) High viscosity index to provide outstanding performance in service applications at extremely high and low temperatures.

(4) Low traction coefficient to reduce power consumption.

(5) Anti-corrosion and rust-proof.

Lubricants with the same viscosity class can also be used; however, their compatibility should be taken2into consideration.

E2 Series Self lubrication Kit for Linear Guideway Application

1. Automation machinery

2. Manufacturing Machines : lnjection molding machines, printing, paper making, textile machines, food processingmachines,wood working machines, and so on.

3. Electronic Machinery : Semiconductor equipment, robotics, X-Y table, measuring and inspecting equipment

4. Others : Medical equipment, transporting equipment, construction equipment.

Relatd Products

What Our Customers Said?

FAQ

Yeah, we have some standard in stock. Including Ball screw with nut, linear guide rail and block, linear module, linear motor and servo motor.

Yes, we can manfacture ballscrew according to customers’ size details drawing or specification, and please offer us below details

1, Ballscrew diameter

2, Thread lead

3, Thread lenght and total ballscrew length

4, End journal configuration

5, Nut configuration

6, Accuracy(lead deviation, geometrical tolerance)

7, Working speed

8, Maximum static load, working load, preload drag torque)

9, Nut safety requirement

10, Lubrication

Usually 45 working delivery days for C5 and P5 accuracy ball screw, but for C7-C10 ballscrew just need 15 working days.

From 50W to 1500W.

We have our own brand, but also we offer HIWIN, Delta, Leadshine, Mitsubishi and others famous brand motor.

Yes, but you need inform us details requirement we need, then our engineer can help you design.

Standard parts: 7-15days.

Non-standard parts: 15-25days.

We will make the delivery as soon as possible with the guarantee quality.

By T/T, for samples 100% with the order; over US $10000, 30% paid for deposit by T/T before production arrangement, the balance to be paid before shipment.

Yes, we can receive.