Curved Guide Rails

Curved Guide Rails

Curved guide rails, also known as curved ARC guide rails, allow the slide to turn clockwise or counterclockwise as it moves in one direction.

Curved Guide Rails Definition: The sliders moves in an arc along the guide rail.

ARC shaped guide rails, also simply called a circular arc guide rail, ensures that the slide always turns in the same direction when moving in one direction: clockwise or counterclockwise.

Product Details

Curved Guide Rails Definition and Classification

Curved arc guide rails are guiding devices in mechanical engineering that enable bidirectional arc motion of slides. Smooth steering is achieved by V-shaped or trapezoidal rollers rolling on the guide surface.

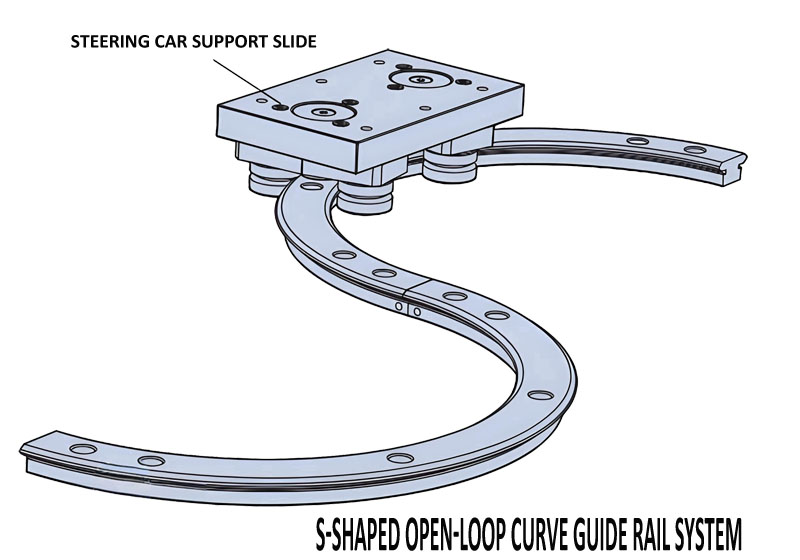

The slides used with curved guide rails are special types: each slide has four rollers, arranged in pairs perpendicular to the direction of movement. These rollers are mounted on a plate, which is then mounted on a special bearing that rotates around its center. This design allows each roller group to rotate along the curved guide rail, ensuring smooth roller movement and preventing jamming.

Curved guide rails are guiding devices in mechanical engineering that enable curved movement of slides, primarily used for connecting linear movements to curved paths in industrial automation. Based on their steering characteristics, guide rails can be divided into two categories: circular arc guide rails (unidirectional steering) and curved arc guide rails (bidirectional steering). Structurally, they employ either V-shaped guide rollers or trapezoidal guide technology. V-shaped guide rails offer high-speed, dust-resistant properties, while trapezoidal guide rails enhance load-bearing capacity.

Based on steering characteristics, Curved Guide Rails are classified as below:

Circular arc guides: Unidirectional steering (clockwise/counterclockwise)

Curved arc guides: Bidirectional steering (can alternate directions

Curved Guide Rails Structure

The device’s matching slide rail uses a four-roller group structure, with special bearings enabling adaptive steering of the roller group to ensure smooth movement. The product’s modular design supports various layout combinations, and different diameters (e.g., 4 meters, 8.6 meters) and transmission methods (gear and rack or synchronous belt) can be customized, achieving a repeatability accuracy of ±0.05mm. Curved guide rails are used in electronics, new energy, medical devices, and automated assembly fields. Typical companies using this technology include Dongguan Yienlong Machinery and Suzhou Yanchuangli Technology.

Curved Guide Rails Main Type

There are two types of arc-shaped guide rails on the market: one uses V-shaped guide rollers, and the other is a newer type using trapezoidal guide technology. V-shaped guide roller rails have V-shaped rollers rolling on a V-shaped guide rail surface, offering the advantages of V-shaped guide rails such as high speed, dust resistance, and long service life. Trapezoidal guide rails have trapezoidal rollers rolling on a trapezoidal guide rail surface, combining the advantages of V-shaped guide rails with a greater load-bearing capacity.

Curved Guide Rails Mainly Applications

Industrial applications: Electronic assembly lines, new energy battery conveying, medical device automation

Special applications: Robotic arm motion trajectories, curved slides for photographic equipment

Relatd Products

What Our Customers Said?

FAQ

Yeah, we have some standard in stock. Including Ball screw with nut, linear guide rail and block, linear module, linear motor and servo motor.

Yes, we can manfacture ballscrew according to customers’ size details drawing or specification, and please offer us below details

1, Ballscrew diameter

2, Thread lead

3, Thread lenght and total ballscrew length

4, End journal configuration

5, Nut configuration

6, Accuracy(lead deviation, geometrical tolerance)

7, Working speed

8, Maximum static load, working load, preload drag torque)

9, Nut safety requirement

10, Lubrication

Usually 45 working delivery days for C5 and P5 accuracy ball screw, but for C7-C10 ballscrew just need 15 working days.

From 50W to 1500W.

We have our own brand, but also we offer HIWIN, Delta, Leadshine, Mitsubishi and others famous brand motor.

Yes, but you need inform us details requirement we need, then our engineer can help you design.

Standard parts: 7-15days.

Non-standard parts: 15-25days.

We will make the delivery as soon as possible with the guarantee quality.

By T/T, for samples 100% with the order; over US $10000, 30% paid for deposit by T/T before production arrangement, the balance to be paid before shipment.

Yes, we can receive.