arc guideway rails

arc guideway rails

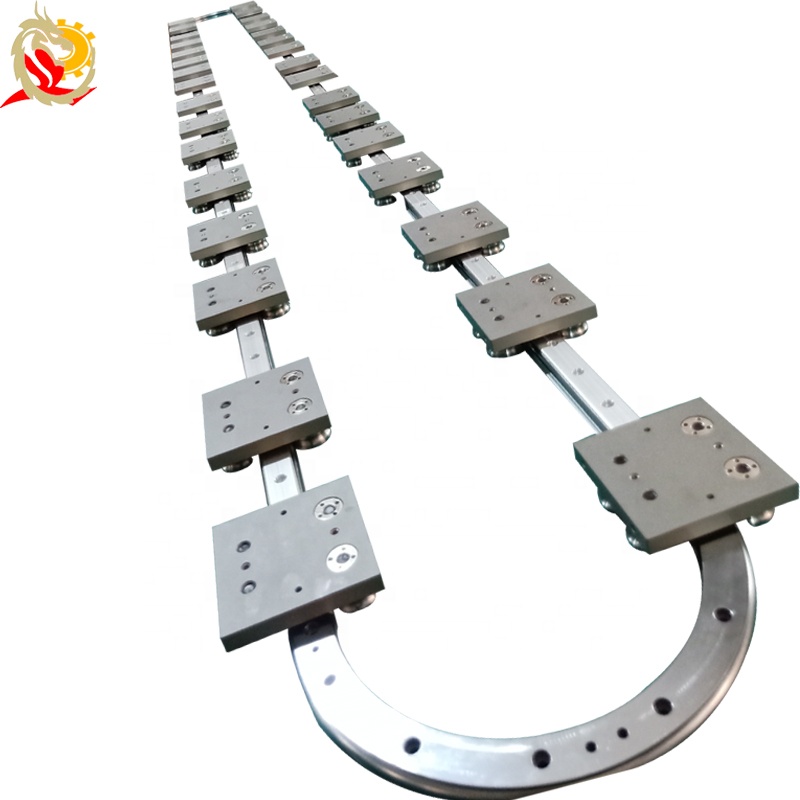

ARC guideway rails are guiding devices in mechanical engineering that enable the arc-shaped movement of slides, primarily used for the arc-shaped connection between linear movements in industrial automation. Based on the slide’s steering characteristics, they can be divided into two categories: circular arc guide rails (unidirectional steering) and curved arc guide rails (bidirectional steering).

Product Details

Circular arc guideway rails are used in high-precision circular guide rail systems for precision automated assembly and machining. Circular arc guide rails (also known as arc-shaped guide rails or ring guide rails) are high-precision industrial devices that achieve circular motion by rolling V-shaped rollers on a V-shaped guide rail surface. Their core structure consists of a modular combination of linear guide rails and circular arc guide rails to form a closed-loop line, possessing high rigidity, low friction characteristics, and multi-station positioning capabilities.

Based on accuracy and load capacity, they can be divided into four types: roller type, precision type, ordinary type, and heavy-duty roller type. The precision type, after heat treatment, achieves a surface roughness of N5 level and can be customized with any arc. This guide rail supports continuous or intermittent motion and is widely used in CNC machine tools, automated production lines, medical devices, and other fields, playing a particularly important role in precision manufacturing processes such as new energy lithium batteries and semiconductors.

ARC Guideway Rails Main Types

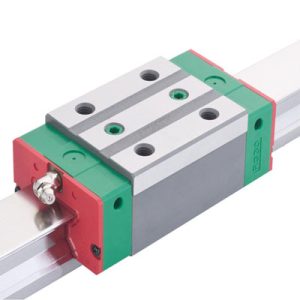

Roller Arc Guide Rail:Features high speed and dust resistance through V-shaped rollers rolling on a V-shaped guide rail surface.

Precision Arc Guide Rail:Achieves N5-level surface roughness after heat treatment; customizable to any arc.

Heavy-Duty Roller Arc Guide Rail:Achieves a maximum load capacity of 30 tons through splicing.

ARC Guideway Rails Application

Industrial Manufacturing: CNC machine tool rotary tables, automated packaging machinery, medical devices, aerospace, new energy lithium batteries, 3C electronics, semiconductors, printing, transportation, packaging industries, biopharmaceutical and vaccine automated production lines.

Emerging Industries: New energy lithium battery assembly lines, 3C electronics testing equipment, semiconductors, printing, transportation, packaging industries, and other automated production lines.

Medical Equipment: Vaccine automated production lines.

Heavy-Duty Scenarios: Heavy-duty models achieve a 30-ton load capacity through splicing.

ARC Guideway Rails Complete Line Introduction

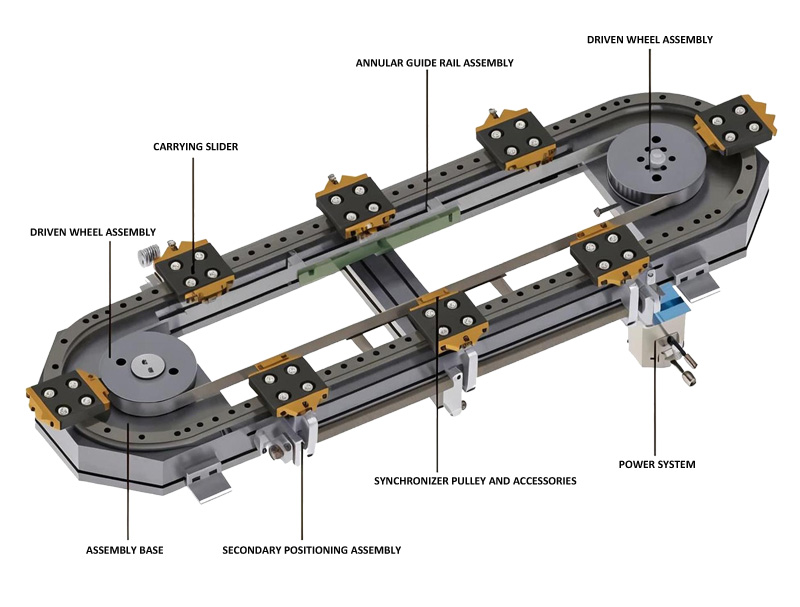

The illustration shows an elliptical circular conveyor belt driven by a synchronous belt, which is also the most common type. Main structural components include: circular guide rail assembly, power system, drive wheel assembly, driven wheel assembly, load-bearing slide, secondary positioning assembly, synchronous belt and accessories, and assembly base. We also provide various other types of circular conveyor belts, such as elliptical, rectangular, circular, and general irregular-shaped circular conveyor belts; synchronous belt circular conveyor belts, chain circular conveyor belts, and connecting rod circular conveyor belts; horizontally mounted circular conveyor belts, vertically mounted circular conveyor belts, etc.

Relatd Products

What Our Customers Said?

FAQ

Yeah, we have some standard in stock. Including Ball screw with nut, linear guide rail and block, linear module, linear motor and servo motor.

Yes, we can manfacture ballscrew according to customers’ size details drawing or specification, and please offer us below details

1, Ballscrew diameter

2, Thread lead

3, Thread lenght and total ballscrew length

4, End journal configuration

5, Nut configuration

6, Accuracy(lead deviation, geometrical tolerance)

7, Working speed

8, Maximum static load, working load, preload drag torque)

9, Nut safety requirement

10, Lubrication

Usually 45 working delivery days for C5 and P5 accuracy ball screw, but for C7-C10 ballscrew just need 15 working days.

From 50W to 1500W.

We have our own brand, but also we offer HIWIN, Delta, Leadshine, Mitsubishi and others famous brand motor.

Yes, but you need inform us details requirement we need, then our engineer can help you design.

Standard parts: 7-15days.

Non-standard parts: 15-25days.

We will make the delivery as soon as possible with the guarantee quality.

By T/T, for samples 100% with the order; over US $10000, 30% paid for deposit by T/T before production arrangement, the balance to be paid before shipment.

Yes, we can receive.