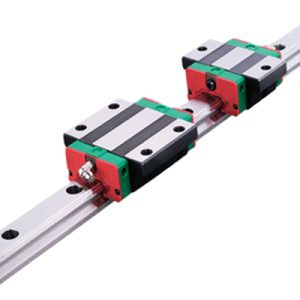

AG Series Linear Guideway

AG Series Linear Guideway

AG Series Linear Guideway is Angle Linear Guideway

Cross-configuration linear guides are precision transmission components that employ a special roller arrangement design. Their core feature is the achievement of four-way load bearing and high-rigidity motion through a cross roller structure.

Angle Linear Guideway Feature

AG series are ground with special procedure to make sure the X-Y translation is in high perpendicularity, which contributes to higher accuracy.

High vertical movement 2 directions

Integrated design and rigidity more than150 %

Assembly height less than 15 %

Angle Linear Guideway Application

Sliding Head Lathe (Swiss lathe)

Vibration Test Machine

Automated

Robot Dispenser

XY moving platform

Measuring instrument,Vertical Lathe

Slant Bed Lathes

Product Details

AG series angle linear guideway is desianed with circular-arc aroove and the same structure as HG series, and areground with special procedure to make sure the X-Y translation is in high perpendicularity.

The integrated designincreases the stifness by 50%, reduces weight and lowers the assembly height by 15%, which contributes to higheprecision translation and achieves higher production quality.

AG Series Linear Guideway Product Features

1. More compact design

Eliminates fastener plate for saving equipment weight and increasing work space

2. High positional accuracyTwo rails are machined with high precision in relative straightness. Extremely high accuracy in verticality is achieved.

3. High torsional rigidityThe rigidity of AG block is 50% higher than a combination of two HG blocks which secured back to back together

The AG series linear guideway only has non-interchangeable type to ensure perpendicularity of two rails. If other accuracy grade is required, please contact us.

AG Series Linear Guideway Typical Application Areas

1. Precision Instruments: Such as optical testing instruments and coordinate measuring machines, requiring nanometer-level positioning stability.

2. Medical Equipment: CT scan tables, X-ray machines, etc., require low vibration and high-precision movement.

3. Semiconductor Equipment: Wafer inspection requires 0.1-micron-level positioning error control.

Note: Compared to traditional guide rails, the cross configuration has a stronger load capacity, but it is more expensive and needs to be selected based on a comprehensive consideration of load and accuracy requirements.

Relatd Products

What Our Customers Said?

FAQ

Yeah, we have some standard in stock. Including Ball screw with nut, linear guide rail and block, linear module, linear motor and servo motor.

Yes, we can manfacture ballscrew according to customers’ size details drawing or specification, and please offer us below details

1, Ballscrew diameter

2, Thread lead

3, Thread lenght and total ballscrew length

4, End journal configuration

5, Nut configuration

6, Accuracy(lead deviation, geometrical tolerance)

7, Working speed

8, Maximum static load, working load, preload drag torque)

9, Nut safety requirement

10, Lubrication

Usually 45 working delivery days for C5 and P5 accuracy ball screw, but for C7-C10 ballscrew just need 15 working days.

From 50W to 1500W.

We have our own brand, but also we offer HIWIN, Delta, Leadshine, Mitsubishi and others famous brand motor.

Yes, but you need inform us details requirement we need, then our engineer can help you design.

Standard parts: 7-15days.

Non-standard parts: 15-25days.

We will make the delivery as soon as possible with the guarantee quality.

By T/T, for samples 100% with the order; over US $10000, 30% paid for deposit by T/T before production arrangement, the balance to be paid before shipment.

Yes, we can receive.