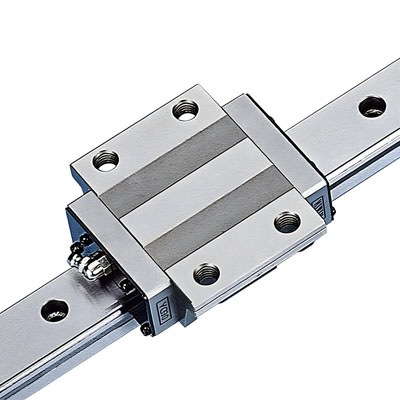

SE series linear guideway

SE series linear guideway

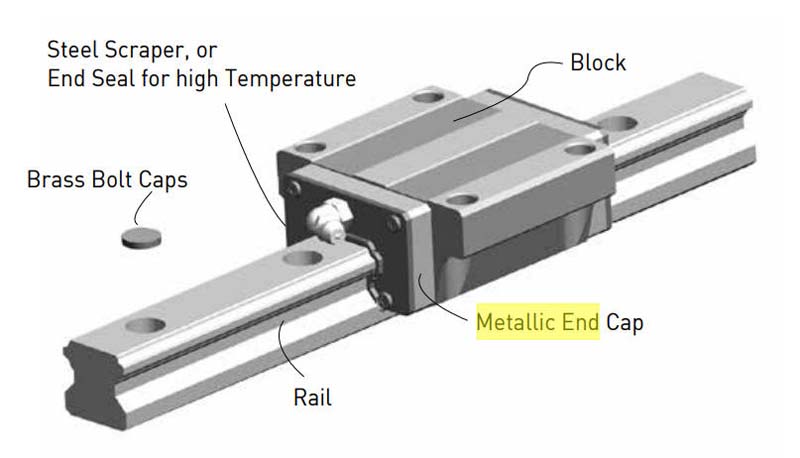

SE series linear guideway is Metallic End Cap Linear Guideway

Metallic end cap type linear guideway are a type of guide with specific temperature resistance properties.

SE Series Metallic End Cap Linear Guideway Feature

Excellent temperature resistance with service temperature up to 150 ℃.

Dust-proof component FKM

Using recirculation component Metallic End Cap

SE series linear guideway Application

Semiconductor equipment

Heat treatment equipment

Vacuum using

Equipment (without vapor dispersion from plastic or rubber at high temperature)

Product Details

SE Series Metallic End Cap Linear Guideway Features

Use of Metallic parts; lif end seal is needed, the high-temperature rubber in end seal is available.

Excellent temperature resistance; service temperature under 150 °C

Applications

Heat treatment equipment,

Applications using vacuums (no vapor dispersion from plastic or rubber)Weldina eauipment.

Stainless Steel Linear Guideway Features

1. Same features as standard linear guideway-Stiffness, Hardness, Service Life, Dimensions remain the same

2. Suitable for specific extreme environments-With metal components, it can be used in low and mediumvacuum environments

3. Great corrosion resistance-Block, Rail, Steel Balls, Grease nipple, Screws are all made ofstainless steel material

Stainless Steel Linear Guideway Suitable for below environments

1. Chemicals 2. Humid

Stainless Steel Linear Guideway Main Applications

Food processing, transportation and storage

Liquid and gas processing equipment

Vacuum equipment

Cleanroom equipment

SE Series Metallic End Cap Linear Guideway Temperature Resistance

The metal end cap type linear guide can withstand temperatures up to 150 degrees Celsius, and can even withstand instantaneous temperatures of 200 degrees Celsius. This design makes it suitable for working environments with high temperature requirements.

Relatd Products

What Our Customers Said?

FAQ

Yeah, we have some standard in stock. Including Ball screw with nut, linear guide rail and block, linear module, linear motor and servo motor.

Yes, we can manfacture ballscrew according to customers’ size details drawing or specification, and please offer us below details

1, Ballscrew diameter

2, Thread lead

3, Thread lenght and total ballscrew length

4, End journal configuration

5, Nut configuration

6, Accuracy(lead deviation, geometrical tolerance)

7, Working speed

8, Maximum static load, working load, preload drag torque)

9, Nut safety requirement

10, Lubrication

Usually 45 working delivery days for C5 and P5 accuracy ball screw, but for C7-C10 ballscrew just need 15 working days.

From 50W to 1500W.

We have our own brand, but also we offer HIWIN, Delta, Leadshine, Mitsubishi and others famous brand motor.

Yes, but you need inform us details requirement we need, then our engineer can help you design.

Standard parts: 7-15days.

Non-standard parts: 15-25days.

We will make the delivery as soon as possible with the guarantee quality.

By T/T, for samples 100% with the order; over US $10000, 30% paid for deposit by T/T before production arrangement, the balance to be paid before shipment.

Yes, we can receive.