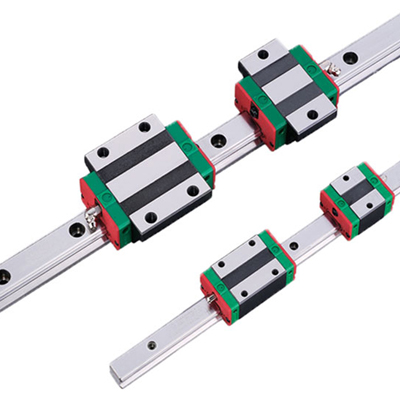

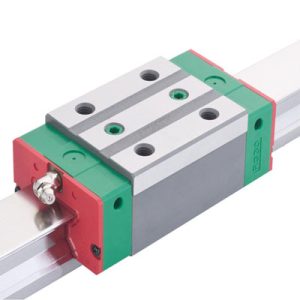

Low Profle Linear Guideway

Low Profle Linear Guideway

Low Profle Linear Guideway also called EG Series Linear Guideway

Low Profle Ball Linear Guideway Feature

With compact size block and lowering assembly height. It also features equal load ratings from all directions and with self-aligning capability to absorb installation errors.

Steel balls contact angle: 45°

Lower assembly height: 15 %

Block length shortened by: 33 %

Low Profle Linear Guideway Application

Automation equipment

Semiconductor equipment

Laser engraving machine

Packaging equipment

Product Details

Features of the EG Series Linear Guideway

The design of the EG series Low Profle Linear Guideway offers a low profile, high load capacity, and high rigidity.

lt also features an equal loadrating in all four directions and self-aligning capability to absorb installation-error, allowing for higher accuraciesAdditionally, the lower assembly height and the shorter length make the EG series more suitable for high-speed.automation machines and applications where space is limited.

The retainer is designed to hold the balls in the block even when it is removed from the rail.

EG series Low Profle Linear Guideway are classified into non-interchangeable and interchangeable types. The sizes of these twotypes are the same as one another. The main difference is that the interchangeable type of blocks and rails can befreely exchanged and they can maintain P-class accuracy.

Because of strict dimensional control, the interchangeabletype linear quideways are a wise choice for customers when rails do not need to be matched for an axis, The modelnumber of the EG series identifies the size, type, accuracy class, preload class, etc.

Relatd Products

What Our Customers Said?

FAQ

Yeah, we have some standard in stock. Including Ball screw with nut, linear guide rail and block, linear module, linear motor and servo motor.

Yes, we can manfacture ballscrew according to customers’ size details drawing or specification, and please offer us below details

1, Ballscrew diameter

2, Thread lead

3, Thread lenght and total ballscrew length

4, End journal configuration

5, Nut configuration

6, Accuracy(lead deviation, geometrical tolerance)

7, Working speed

8, Maximum static load, working load, preload drag torque)

9, Nut safety requirement

10, Lubrication

Usually 45 working delivery days for C5 and P5 accuracy ball screw, but for C7-C10 ballscrew just need 15 working days.

From 50W to 1500W.

We have our own brand, but also we offer HIWIN, Delta, Leadshine, Mitsubishi and others famous brand motor.

Yes, but you need inform us details requirement we need, then our engineer can help you design.

Standard parts: 7-15days.

Non-standard parts: 15-25days.

We will make the delivery as soon as possible with the guarantee quality.

By T/T, for samples 100% with the order; over US $10000, 30% paid for deposit by T/T before production arrangement, the balance to be paid before shipment.

Yes, we can receive.