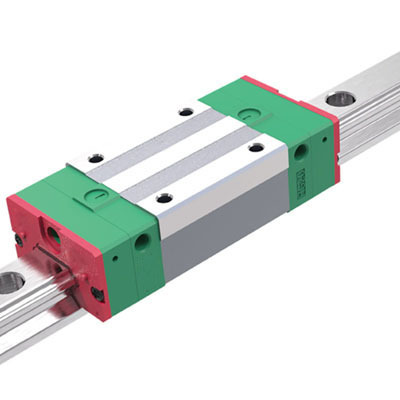

EL Self-Lubricant Linear Guideway

EL Self-Lubricant Linear Guideway

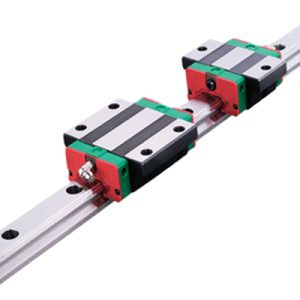

The EL self-lubricat linear guideway module is specially designed for for MG, HG, and QH series linear guideways. This module can be directly installed at both ends of the block, features an oil-containing material and capillary structure that continuously releases lubricant during block operation. It achieves long-lasting automatic lubrication, reduces maintenance frequency, and extends product life.

Lubrication mileage:20000km Fullfill cleanroom class: ISO 6

EL Self-Lubricant Linear Guideway APPLICATION

Medical equipment

Semiconductor and electronics industry

Automation machinery

Precision measuring instruments

General industrial machinery

Product Details

EL self-lubricat linear guideway are precision transmission components integrating self-lubricating technology. Their core feature is long-term stable lubrication through a built-in lubrication system, eliminating the need for an external oil supply system.

EL Self-Lubricant Linear Guideway Main Features:

1. Maintenance-Free Design: Built-in cartridge oil tank and oil-cotton structure automatically lubricates the balls and raceways through diffusion, reducing friction and wear, and extending service life.

2. Environmentally Friendly and Flexible: No oil leakage or contamination, suitable for environments with high cleanliness requirements (such as semiconductors and medical equipment). Lubrication is possible regardless of the slider’s orientation, with no directional limitations.

3. High Load Capacity and Precision: Utilizing a ball-circulating structure, it can withstand high loads while maintaining micron-level motion accuracy, suitable for high-precision applications such as CNC machine tools and automated equipment.

EL Self-Lubricant Linear Guideway Application:

Industrial Equipment: CNC machine tools, plastic machinery, printing machinery, etc.

Special Environments: Dust, humid, or cleanrooms, due to its excellent dustproof and sealed design.

Maintenance Tips: Remove rust-preventive oil before first use to avoid diluting the lubricant. Lithium-based grease-compatible lubricant is recommended.

Relatd Products

What Our Customers Said?

FAQ

Yeah, we have some standard in stock. Including Ball screw with nut, linear guide rail and block, linear module, linear motor and servo motor.

Yes, we can manfacture ballscrew according to customers’ size details drawing or specification, and please offer us below details

1, Ballscrew diameter

2, Thread lead

3, Thread lenght and total ballscrew length

4, End journal configuration

5, Nut configuration

6, Accuracy(lead deviation, geometrical tolerance)

7, Working speed

8, Maximum static load, working load, preload drag torque)

9, Nut safety requirement

10, Lubrication

Usually 45 working delivery days for C5 and P5 accuracy ball screw, but for C7-C10 ballscrew just need 15 working days.

From 50W to 1500W.

We have our own brand, but also we offer HIWIN, Delta, Leadshine, Mitsubishi and others famous brand motor.

Yes, but you need inform us details requirement we need, then our engineer can help you design.

Standard parts: 7-15days.

Non-standard parts: 15-25days.

We will make the delivery as soon as possible with the guarantee quality.

By T/T, for samples 100% with the order; over US $10000, 30% paid for deposit by T/T before production arrangement, the balance to be paid before shipment.

Yes, we can receive.