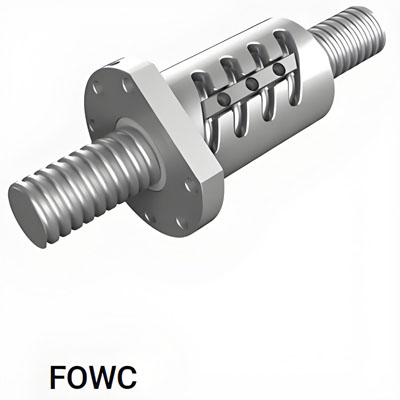

External Ball Screw

External Ball Screw

External ball screw are a common type of transmission device. Their core feature is that the balls temporarily detach from the screw’s threaded raceway during circulation, completing the cycle through a helical groove or insert on the outside of the nut.

External Ball Screw Type

There are two types of Ballnut of the external circulation Ballscrews. They are “immersion type” of A and “extrusive type” of B. The “immersion type” means the ball circulation tubes are inside the circular surface of Ballnut as shown on specifi cations of this catalogue are of “immersion type”.

Structural Principle

1. Circulation Method: The balls return to the screw-nut area via a helical groove or insert on the outer surface of the nut, re-entering the cycle.

2. Typical Structures:

(1) Insert Type: Connects the raceway via a steel pipe; simple structure but large radial dimension.

(2) Spiral Groove Type: Simple manufacturing process, but the ball retainer is prone to wear.

Product Details

External Ball Screw Features

1. Lower noise due to longer ball circulation paths.

2. Off ers smoother ball running.

3. Off ers better solution and quality for long lead or large diameter ballscrews.

In some cases, as per designs on customer’s drawings, there are smaller outer diameters ballnuts required. Then the ball circulation tubes shall extrude out of Ball nut circular surface.

Performance Characteristics

Advantages: Simple manufacturing process, low cost. Wide circulation adaptability, low installation space requirements.

Disadvantages: Larger radial dimension, affecting compactness. Uneven raceway joints may cause jamming or noise. Rapid wear of the ball retainer, requiring regular maintenance.

Application Scenarios

Heavy-duty applications: Such as heavy machine tools, construction machinery, and other high-load applications.

Low-precision requirements: Suitable for equipment with low transmission precision requirements.

Technical Improvements

Recent patents show that the external circulation structure can reduce external impurity contamination and improve load-bearing capacity through built-in circulation components (such as the return hole and guide ball tube inside the lead screw).

Relatd Products

What Our Customers Said?

FAQ

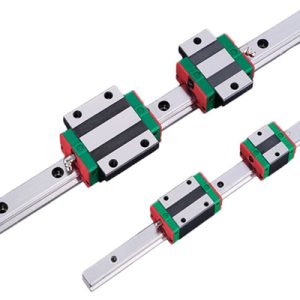

Yeah, we have some standard in stock. Including Ball screw with nut, linear guide rail and block, linear module, linear motor and servo motor.

Yes, we can manfacture ballscrew according to customers’ size details drawing or specification, and please offer us below details

1, Ballscrew diameter

2, Thread lead

3, Thread lenght and total ballscrew length

4, End journal configuration

5, Nut configuration

6, Accuracy(lead deviation, geometrical tolerance)

7, Working speed

8, Maximum static load, working load, preload drag torque)

9, Nut safety requirement

10, Lubrication

Usually 45 working delivery days for C5 and P5 accuracy ball screw, but for C7-C10 ballscrew just need 15 working days.

From 50W to 1500W.

We have our own brand, but also we offer HIWIN, Delta, Leadshine, Mitsubishi and others famous brand motor.

Yes, but you need inform us details requirement we need, then our engineer can help you design.

Standard parts: 7-15days.

Non-standard parts: 15-25days.

We will make the delivery as soon as possible with the guarantee quality.

By T/T, for samples 100% with the order; over US $10000, 30% paid for deposit by T/T before production arrangement, the balance to be paid before shipment.

Yes, we can receive.